PTP Audio

PTP Audio

PTP Audio is the company of Peter Reinders and is founded on years of experience in audio in general and in Lenco especially.

Peter Reinders has been interested in audio for as long as he can remember and because he was born in 1963, vinyl is what he grew up with. Peter got his first turntable (a Lenco!) when he was about ten and it went on from there.

Along the way Peter graduated as an Industrial Designer at Delft University and has been a designer for his whole working life, gaining lots of experience in all aspects of product development.

In 2005 Peter joined the Lenco revival when he built his first Lenco based turntable. Immediately he began thinking about ways to improve it. In the end this led to the first PTP, an innovative top plate to replace the flimsy original. He used it to make his next model:

In hindsight this is where PTP Audio started. Peter received so many requests for these plates that he simply had to make more and he has been producing them ever since. Over the years several improvements were made, the current models are the PTP5 and PTP6. If you are interested in these plates have a look at the PTP section of Lenco Heaven

In the wake of the PTP’s success quite a few people asked Peter whether he sold complete PTP based turntables. This triggered his creativity and he started to think about a possible design. The result is what you see here on the PTP Audio website: Idler drive turntables, which combine the best parts from Lencos of the sixties and seventies with the best modern materials, design and production techniques.

The foundations PTP Audio is built on:

Lenco

Lenco began in 1946 in Burgdorf, Switzerland and was founded by Fritz and Marie Laeng. They mainly produced turntables but made other audio components as well. Their heyday lay in the Sixties and Seventies when thousands of L70, L75, L76 and L78s were produced. All these models shared the same basic technology. They were all idler driven and used the same strong motor and heavy die cast platter. Lencos were built like tanks and most of them still work flawlessly today. All these models were sold under many different names, most importantly Lenco in continental Europe, Goldring in the UK and Bogen in the US but many other varieties exist.

When fashion changed in favour of belt and direct drive the company went into decline. The Dutch STL Group bought the rights to the Lenco name in 1997. You can still buy Lenco labelled products today but they have nothing in common with the original Lencos from Switzerland.

An original Lenco L70.

An original Lenco L70.

Lenco Revival

The rediscovery of Lenco idler drives is quite a recent event. Until a few years ago Lencos were simply forgotten about or worse, dismissed as rumble machines.

Only when a thread appeared on Audiogon in 2004, in which the Lenco idler system was praised as the basis for a really good turntable, things started to change, albeit very slowly. The claim that a Lenco based turntable could be as good as the best was laughed away at first but when a few people took the plunge and built one, they had to admit it was true. Peter was one of those early builders hasn't looked back since.

It grew from there, the thread became the largest ever on Audiogon and different forums dedicated to Lenco were started along the way. Currently the most complete source for information has to be Lenco Heaven with thousands of members from all over the world.

The Lenco revival has been a DIY phenomenon more than anything. Hundreds of enthusiasts have built their own players, all based on Lencos but all with different designs and often different principles behind them. Many have subsequently sold their old and often expensive turntable because they liked their Lenco more.

A typical DIY project.

A typical DIY project.

The PTP (Peter’s Top Plate)

A Lenco is a very good starting point if you want to make a top quality turntable, but it is not without its faults. Its main weakness is the top plate. It is made out of relatively flimsy pressed steel plate, which makes it prone to vibrations. Plinth building is made unnecessarily complicated by the recess under the platter and at the same time this recess makes it difficult to achieve correct VTA because the platter rides so low relative to the armboard.

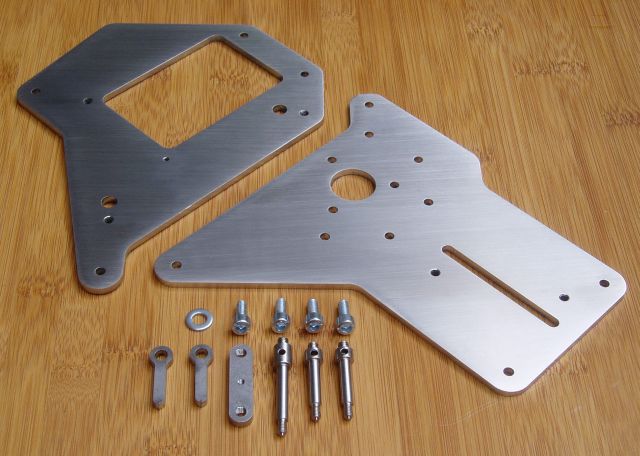

In 2006 Peter designed the PTP as a solution to these problems. Made from 4mm thick stainless steel and laser cut into the right shape. All PTPs have a separate island for the motor. This innovation prevents vibration from the motor reaching the bearing through the plate. Since 2006 the PTP has been constantly produced and along the way several improvements have been made. The current versions are the PTP5 and PTP6. The PTP5 forms the basis of all turntables PTP Audio makes.

The PTP5 kit.

The PTP5 kit.

PTP Audio

Until now, if you lacked the skills or the time to build something yourself, it was near to impossible to buy a ready-to-use idler drive turntable. That is why we started PTP Audio.